Gage begins operations in new plant with focus on workplace culture

Oct. 15, 2018

This paid piece is sponsored by the Sioux Falls Development Foundation.

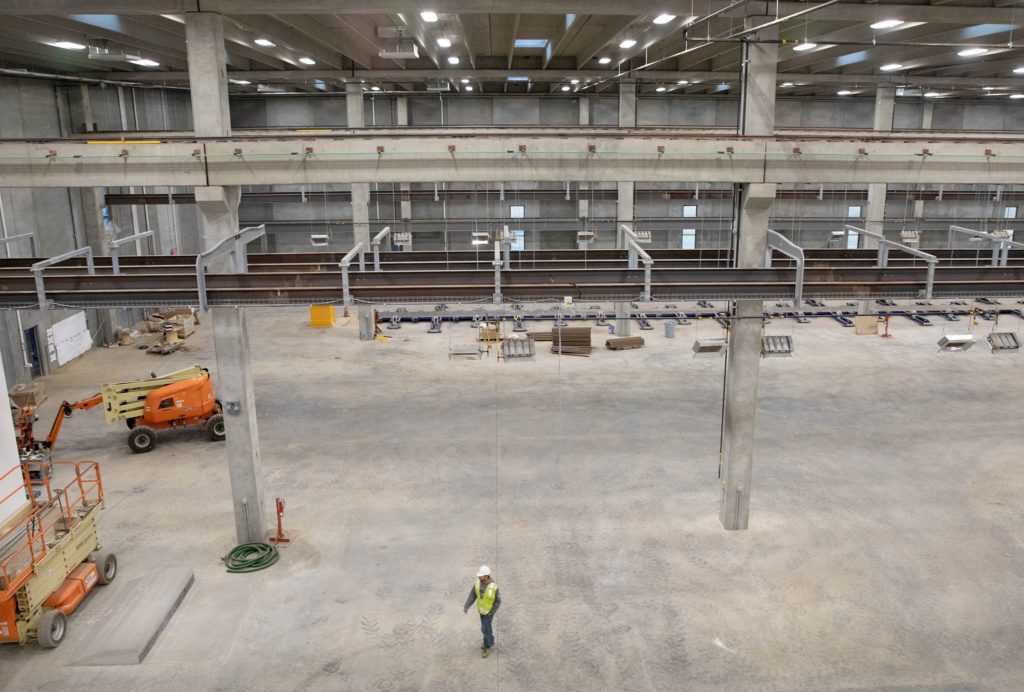

Gage Brothers Concrete Products will start mixing its first concrete in northeast Sioux Falls this month as it begins relocating operations from the site it has occupied for more than a century on West 12th Street.

At 200,000 square feet, it’s the nation’s most automated precast plant. The approximately 250 people who will work there will find a place with higher ceilings, a lot more natural light and the capacity to move most of the work indoors.

But those are just the obvious changes.

Beneath the surface, Gage has been working for months to create a culture that can adapt and thrive for the company’s future.

“The processes that need to change are one thing, but the culture change that needs to take place to have that happen is probably every bit as daunting of a task,” president Tom Kelley said. “We’re truly bending over the silos.”

Gage is transitioning from a vertical organizational structure to a more horizontal one, encouraging teams to think about how they contribute to the entire manufacturing process instead of one part of it.

“It’s three generations of family, and we wanted to still maintain that culture,” Kelley added. “What we learned is we still have to have that ‘clan’ culture and, of course, that supports a more horizontal structure too.”

Here’s how much of a family business Gage Brothers is: Jeff Ishmael got connected to the company through his brother, who encouraged him to join the team.

He has stayed for 23 years and been promoted multiple times. He has served as crane crew foreman for the past decade.

“It’s wonderful,” he said. “You have so much opportunity to learn, to move up, to play with big toys.”

Ishmael also has been part of the company’s culture shift. He describes it as a place where employees now work toward common goals: getting the job done well and going home safely.

“The cooperation with every department has changed dramatically,” he said. “It’s one for all. We’re all together as a team.”

That unity is helping his team as they move into their new space, he said.

“We have the opportunity to work with brand-new, state-of-the-art equipment, top-notch. I can’t wait,” he said. “My team’s excited about it. It will be a learning process for us all, but it’s a challenge we’re all looking forward to.”

Gage also has paid attention to the unique needs of its younger workers, Kelley added.

“They want to make a difference, and they want constant feedback,” he said. “Give them some autonomy, give them a challenge, and give constant feedback. That’s helped. We have a wealth of young folks ready to take on new tasks, and that’s exciting.”

While it’s an ongoing effort, the approach has been effective so far. Gage has reduced its annual turnover from 70 percent three years ago to 34 percent.

Here are some additional ways the company is accomplishing its culture shift:

- Attention to onboarding. New hires are matched with a buddy to help acclimate them to work.

- Focus on teaching. Managers are reminded to allow time for educating new hires and to set expectations realistically.

- Access to leadership. After the first 90 days, employees are invited to a quarterly lunch to give feedback and ask questions.

- Training for all. The plant’s new technology is causing jobs to shift, and training is being provided to all staff, along with some individual coaching.

- Team building. A voluntary wellness program with friendly competitions and a staff outing to escape rooms have helped build teamwork.

- Use outside help. Gage contracted with consultant Maggie Owens of Human Capital Consultants to help implement its culture change.

To see more workforce development strategies, read the latest edition of WIN: Workforce Information Now from the Sioux Falls Development Foundation.