Supply chain challenges? This will help

June 7, 2022

This paid piece is sponsored by South Dakota Manufacturing & Technology Solutions.

There are no quick solutions to supply chain challenges, especially in manufacturing. But there are strategies that can help.

You can learn many of them in just one day at an upcoming workshop organized by South Dakota Manufacturing & Technology Solutions.

“Since COVID especially, supply chain issues have been an enormous challenge,” said Chad Goldammer, a financial business adviser with MTS.

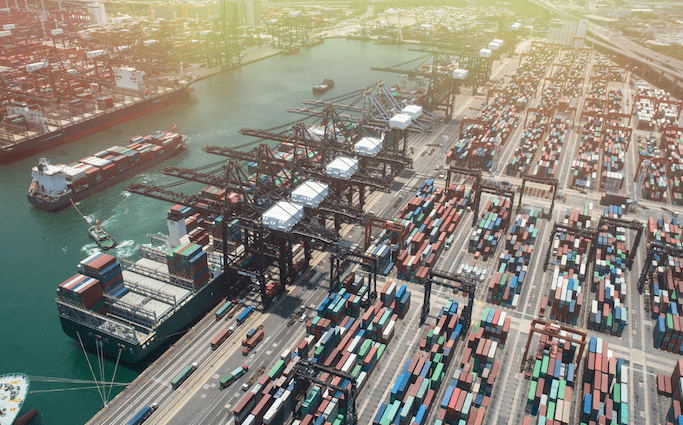

“We hear it a lot from the businesses we work with, everything from a lack of truck drivers to a warehouse shortage and, of course, the issues with the ports overseas.”

The workshop will begin with a session on supply chain fundamentals and walk through topics such as supply chain management strategy, total cost of ownership, TCO strategic reduction, supply chain risk management, and contracting and negotiation tactics.

The afternoon features hands-on guidance in assessing your business and developing a supply chain road map. You’ll leave with an assessment of your supply chain strategies, metrics on where you want to target improvement strategies, programs and plans for making your supply chain management stronger in your company, no matter the size.

The Sioux Falls event will be from 8:30 a.m. to 4:30 p.m. Monday, June 13, at the Holiday Inn & Suites – Airport, with other workshops to follow in Yankton, Watertown and Deadwood.

Anyone involved in supply chain-related duties and decisions will benefit, said Shane Barber, chief operating officer of Denver-based Business Excellence Group, which is a presenting partner for the event.

“A lot of the time, we’re finding manufacturers playing the victim,” he said. “When I walk through manufacturing floors, I go right to the scrap bins where they throw away precious materials. They’re often not managing their materials or processes as they could. We want to be sure there are materials management and process improvements in place because that’s something they control no matter where the supply chain is at.”

Focusing on what you can control, from your diversity of vendors to how you’re actively managing those relationships is key, he said.

“We’ll also talk about what constitutes the total cost of ownership in the supply chain, from raw materials all the way to end consumer destination, and then how do you get proficiency both inside your four walls and outside them.”

Here are key takeaways you can expect from the workshop:

- How to reduce your cost of ownership all the way to shipping.

- How your supply chain truly impacts your bottom-line costs and top-line revenue.

- Knowledge of your supply chain complexity and key areas of improvement.

- How to properly manage your own material in your own walls.

- How your supply chain management strategy can drive a competitive advantage for your company.

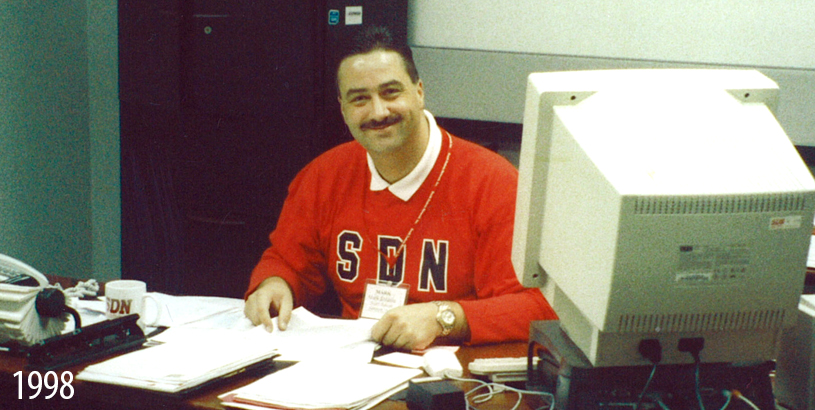

The presenter will be Anthony Russo, one of Barber’s colleagues at Business Excellence Group + TradeHub International, who has spent more than 15 years helping companies establish sourcing and sales relationships around the world. An expert in international business, he focuses on creating import/export strategies for companies entering new markets.

Russo has partnered with overseas American chambers of commerce, universities, World Trade Centers, governments and associations. He has held the titles of director of education and trade services for the South Carolina World Trade Center, director of trade services for the World Trade Centers Association in New York, director of trade service for the World Trade Center Denver, president of THI Mexico and international sales manager for a number of clients.

“There’s not a question he won’t be able to answer from the crowd,” Barber said. “He has plenty of stories and a background that complements this workshop perfectly.”

To learn more and register for the workshop, click here.

Following the workshop series, MTS plans to continue supporting manufacturers with supply chain challenges through a peer group that is being formed.

“The peer group will hopefully serve as a continuation of what attendees will hear about in these workshops. The groups are intended to have all those working in supply chain/purchasing to get a group of local people that they can share best practices with, bounce ideas off of and create potential partnerships with future supply chain/purchasing concerns,” Goldammer said.

“Most supply chain departments are one or maybe two people in South Dakota. There’s potentially not a lot of support, and a lot of things fall on their desk. So we’ll talk through best practices, look at how other industries are working to get their supply chain back running, work on cash flow issues, and we’re hoping to attract everyone, from those who have been in this industry for decades to those who maybe got thrown into it recently.”

The plan is for the group to begin meeting in July, likely meeting monthly thereafter.

“We’ve had a number of manufacturers ask us about doing something like this, so we’re excited to put this together and hope to get a good mix of people so everyone can take something away from it.”

To get connected to the peer group, fill out the contact form here.