Under-the-radar precision manufacturer finds fast growth in services for aerospace, defense industries

Nov. 3, 2022

This paid piece is sponsored by South Dakota Manufacturing & Technology Solutions.

In less than three years, a Sioux Falls manufacturer has grown to work with some of the biggest players in aerospace and defense.

From its location in northeast Sioux Falls, Rensberger Technologies focuses on creating the challenging, custom components needed for aerospace and defense equipment, along with medical devices and other custom manufacturing work.

“It’s similar to a puzzle; we produce the challenging pieces that our customers need to complete their design,” said operations manager Jill Koens, who joined the team early this year after a dozen years working for other area manufacturers.

“We’re challenged, and I like a challenge. It’s a small team that works well together, and we’re very busy right now. We have a lot going through the shop in different areas.”

All the work done here is specific to customers’ needs, said Nate Grosz, who has led the sales and business development efforts since the company was founded in early 2020 by local entrepreneur Ron Rensberger.

Nate Grosz, Ron Rensberger, Jill Koens

It began when Rensberger bought the building that used to include Midwest Tool & Die.

“Ron brought on board some of the high-level talent they had as well as high-level talent from other areas of the region and started new from there,” Grosz said. “We created a completely new and different entity that focuses on providing precision manufacturing solutions to complex projects.”

About 95 percent of the company’s customers are on the coasts or in the South, he estimated.

“There would be some big-name players you would know that we can’t disclose. A lot of them are prime aerospace and defense contractors that partner with us for machined flight-focused products.”

These are key structural pieces to an advanced weapons threat detection system for a prime defense contractor on one of the coasts.

Working with clients of that nature demands that a business such as Rensberger be able to prove it does quality work, which is why it sought AS9100 certification for more than a year.

“It was a long process,” Grosz said. “We had customers waiting for our certification, and they couldn’t work with us until we had it.”

The company worked with South Dakota Manufacturing & Technology Solutions as a guide through the complex road to achieving certification.

“Rensberger is unique in having precision equipment capable of holding very tight tolerances in addition to an outstanding quality department,” said Brad Fischer, a business adviser at MTS, who worked with the company through the certification process.

“AS9100 certification is critical when working with aerospace clients but also gives them an advantage with other industries that may have suppliers that are not certified or only certified to ISO 9001. My guess is less than 1 percent of South Dakota companies are registered to AS9100.”

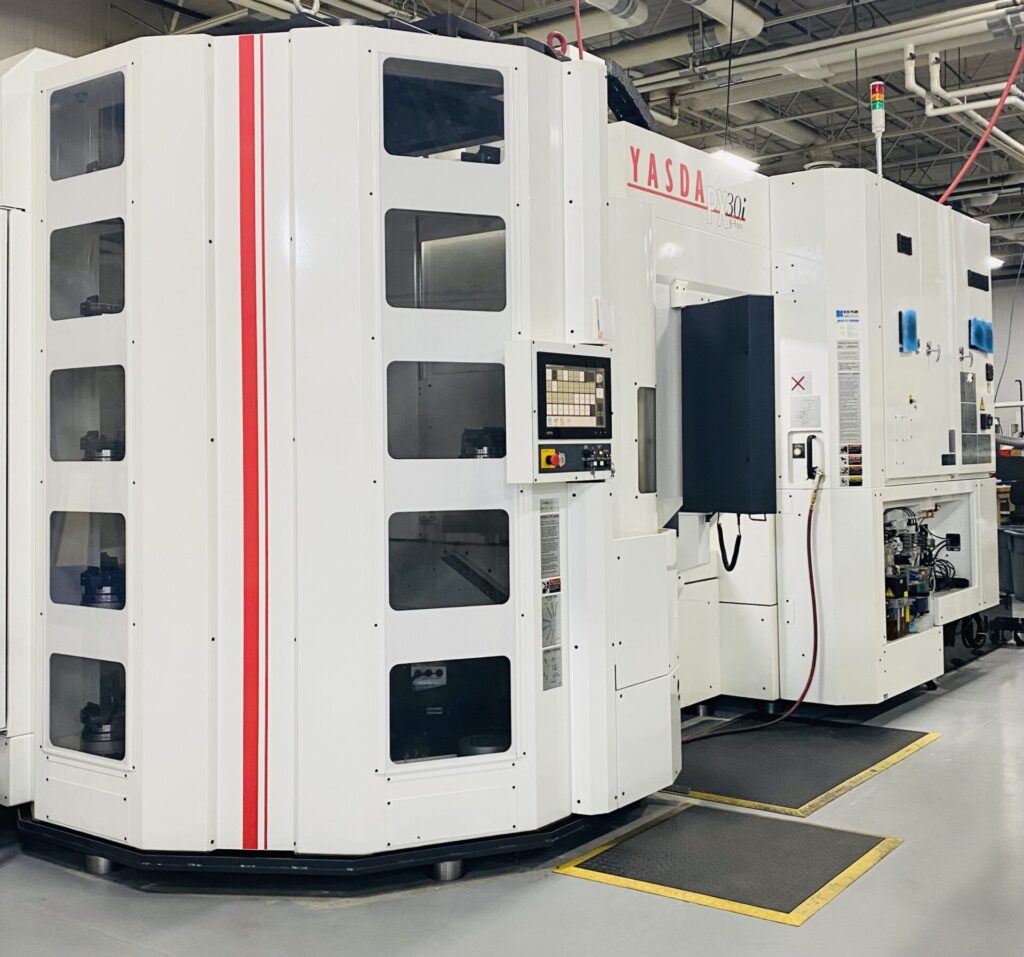

This Yasda PX30i precision machining center combined with other unique manufacturing technologies allow world-class machining capabilities at Rensberger.

Companies need to prepare applicable documents required by AS9100, which are based on a detailed study of all activities of the organization. That includes a quality manual, quality procedures, identification of appropriate and defined regulatory requirements and confirmed compliance with the regulatory requirements, standard operating procedures and formats to establish the objective evidence of execution and to confirm control over all the activities.

They also need to train all employees within the organization, conduct internal audits to check readiness for the certification and conduct management review meetings in the presence of top management to guide the organization for the actual implementation of all the issues related to quality management systems.

“We were a new company struggling at the beginning of COVID-19; being able to utilize MTS services was a huge win for us,” Grosz said. “To have support locally meant we didn’t have to fly someone in from a larger city to help for a week at a time. Brad was here every week to meet with Ron, myself and other members of our team. It was very beneficial.”

Fischer and MTS also helped Rensberger with cybersecurity compliance assessment and to develop an SSP — system security plan — and a POAM, or plans of action and milestones.

“Brad was like our guide along a long road trip,” Grosz said. “If we got into any issues, he would walk us through the steps required to implement the standard into our business. Now, we are putting these policies and procedures to use every day. If we don’t do something right, we use our new quality manual as a guide to make sure we don’t make the same mistakes twice.”

Rensberger received its AS9100 certification a few months ago, and the business has seen a 300 percent increase in sales since becoming certified.

“I always say let’s keep growing and bringing in more to see what we can do,” Koens said. “I feel like the sky is the limit.”

These are precision lathe parts made out of a material called Inconel. It’s an extremely strong — expensive — material that even allows for parts like this to be used in space.

The certification now allows the company, which has about 15 employees, to compete at the highest level in its industry, Grosz added.

“I think it’s a special place to be,” he said. “We have a lot of skilled talent here; many are some of the best at what they do. Our team’s ability to tackle challenges while remaining efficiency minded has allowed us to partner on some really cool projects. We’re manufacturing parts that very few places in the country can make, and it’s happening here, and South Dakotans are making them.”

Rensberger Technologies is hiring positions in quality, technology, management and manufacturing. To learn more, call 605-373-1160 or email [email protected].

To learn more about the services provided by South Dakota MTS, click here.