Family-owned manufacturer brings new jobs to hometown thanks to these strategies

April 11, 2022

This paid piece is sponsored by South Dakota Manufacturing & Technology Solutions.

Linda Scher knew her family business needed some help – and that she couldn’t provide it alone.

She took over as CEO of Huron-based Horizontal Machining & Manufacturing Inc., or HMMI, in mid-2017 following the death of her father, Earl Nordby, who had founded the business. She and her sister, Diane DesLauriers, are co-owners.

“My dad was an entrepreneur through and through,” she said. “He built a career as a Pepsi bottler and rented excess space in the warehouse to some guys who had a CNC machining center and expanded into fabrication.”

When the price of steel went up, Nordby came in as an angel investor “and fell in love with the industry,” Scher said. “He loved manufacturing and could see the possibilities and kept adding and adding and adding.”

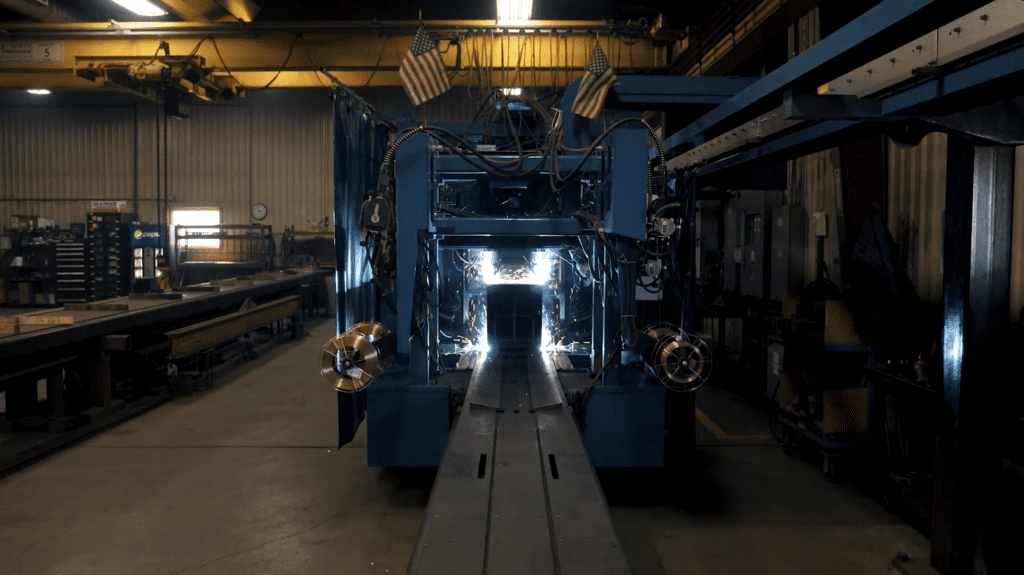

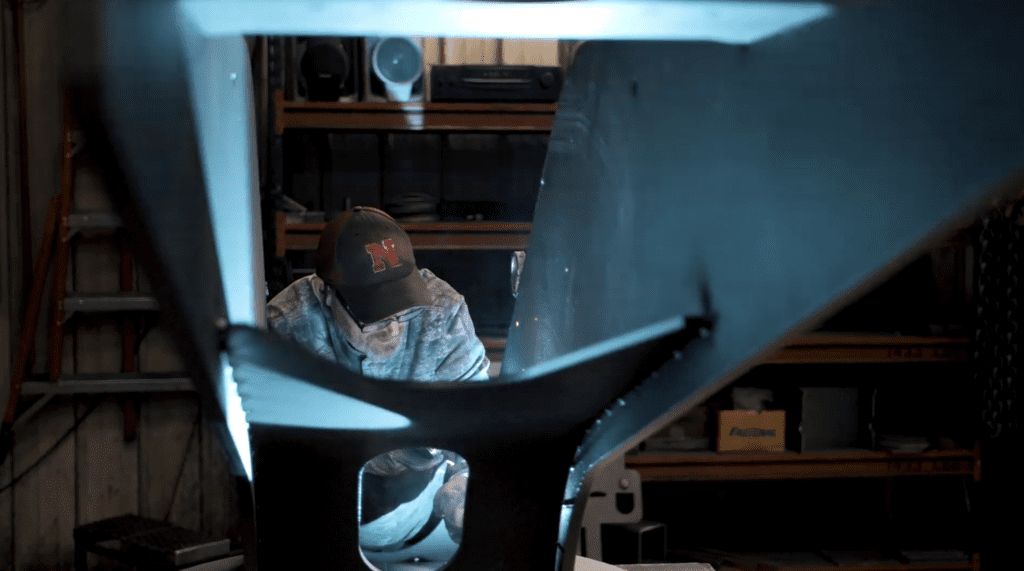

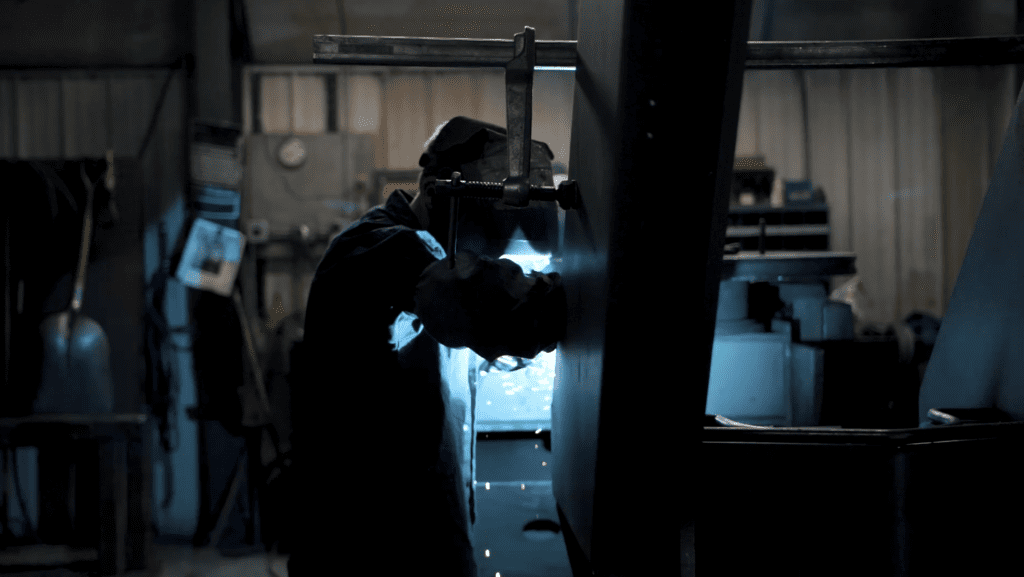

From 1997 to his death in 2016, Nordby built HMMI into a 100,000-square-foot one-stop shop for contract manufacturing of large and heavy steel products, including fabrication, welding, machining, painting and complete assembly.

“It is all start to finish under one roof,” Scher said. “While we serve multiple industries, currently most of our customers are in the mobile crane business, and we build most large, critical components for mobile cranes.”

Scher inherited her father’s entrepreneurial spirit. In addition to serving on the board of HMMI before his death, she ran her own firm managing professional associations such as medical groups and legal associations.

“My firm would be planning conferences for 3,000 people in Spain or board meetings in New York City for 20, working with boards and committees. It was very different from manufacturing, but business principles are business principles,” she said.

And the business leader in her recognized that if HMMI didn’t make some changes, dozens of jobs in her hometown of Huron could be at risk.

“I could see our on-time delivery needed help,” she said. “And I knew about lean manufacturing and knew we had to bring in some lean processes to get that under control.”

She also knew she needed additional expertise.

“The key was finding the right people, and I was lucky to be introduced to MTS,” she said.

MTS, or South Dakota Manufacturing & Technology Solutions, began working with HMMI to assess the company’s needs.

“We went through an enterprise assessment questionnaire and took some low-hanging fruit to give us some immediate wins on the shop floor, improved our culture and helped us determine our key performance indicators,” Scher said.

“MTS helped us throughout the company, from accounting and analysis through the shop floor. We started with a value stream mapping exercise and then picked some areas where we could get some really big gains.”

The company went from a 12-week lead time to a six-week lead time, with MTS going “area by area, machining and painting and welding; they could just see instantly the largest areas for opportunity and where quick changeovers would be most beneficial,” Scher continued.

Within nine months, HMMI had gone from 40 percent on-time delivery to 95 percent. Employee morale improved as did the company’s standing with customers.

“So it was dramatic, and it endeared everybody to lean processes and to MTS,” Scher said.

“MTS was just so important in building our team and being part of our team.”

HMMI continues to partner with MTS as needs arise.

“Continuous improvement is a term for a reason,” Scher said. “Our product mix has changed, and then with COVID and supply chain disruptions, we needed MTS’s help again. Even though we now can do our own value stream mapping exercises, we continue to use MTS all the time.”

In addition to value stream mapping and project work, all the company’s managers have gone through the MTS lean certification course, “so everyone has the same language,” and the leadership has gone through the Lean Leadership for Supervisors course with MTS.

“MTS does such a beautiful job training everyone,” Scher said. “And now we’ve gone one deeper to include the leads on the floor, so they’re helping us train our next generation of managers, plus making sure we have a uniform onboarding and training process.”

All these efforts continue to produce results, she added. In February, deliveries in HMMI’s most backlogged area increased by 47 percent.

“The 47 percent increase in a short month is incredible,” Scher said. “We can’t wait to see further productivity gains from processes we’ve been putting in place.”

The proof is in the numbers – across the board.

“When we began with MTS, we weren’t profitable, and now we are. That immediate first-year flip was just incredible,” Scher said. “We’ve done an employee survey the last three years, and every year the feedback gets better. This was our best year yet despite the fact that last year was stressful with supply chain issues. Having MTS step in and help us find order on the floor helps with morale, which means greater retention of our skilled workforce.”

At the time Scher took over as CEO, HMMI had about 65 employees. Now, the team is at 100 and growing.

“Being able to keep those jobs in Huron was so important to me and my sister and our family legacy,” she said. “HMMI has good people who have worked hard building this company, so for it to have to close would have been heartbreaking.”

And they soon will have even more co-workers.

“We hope to end the year with 120 people, so we’re definitely creating jobs. We could not have done it without MTS,” Scher said. “They know this stuff. They can walk in, help us identify problems and know they’re solvable.”